26,000L-20′ ISO TANK CONTAINER Specification

|

| CAPACITY |

26,000 Litres |

| Frame (L/W/H) |

6058/2438/2591mm |

| TARE MASS |

3,800 kg |

| MAX GROSS MASS |

36,000 kg |

| PRODUCTS |

General purpose liquids |

| HYDROSTATIC TEST PRESSURE |

6 bar |

| VESSEL DESIGN TEMP |

-40℃ to 130℃ |

| TEMPERATURE (@atm P) |

140℃ |

| DESIGN CODE |

ASME Ⅷ DIV. 1 |

| TYPE APPROVALS |

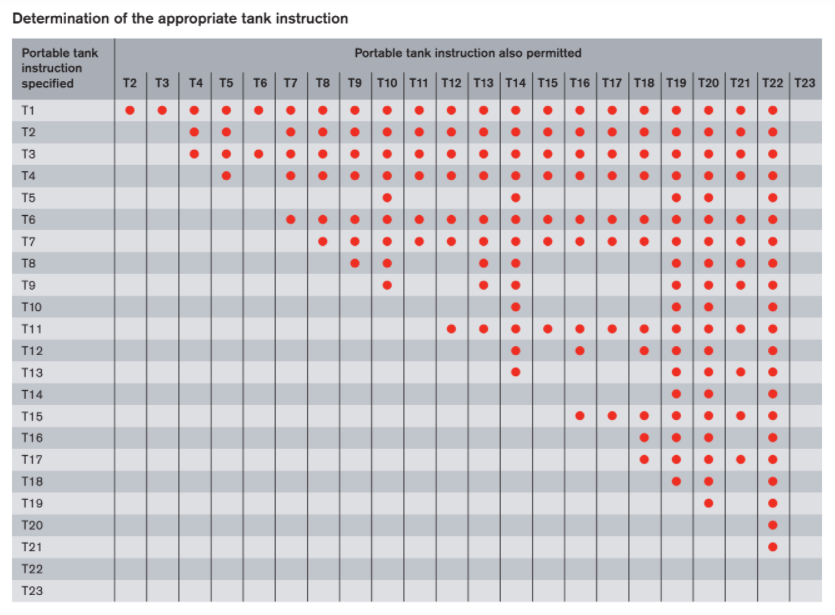

UN portable tank (T11 IMDG, CFR49, ADR/RID), UIC, TIR, CSC, TC, ADR L4BN |

| CLASSIFICATION |

Bureau Veritas |

| STACKING TEST |

Each container is approved for 9 high stacking at 24,000kg |

| SAFETY RELIEF ASSEMBLY |

2½” BSP safety relief valve without gauze. Pressure only model set at +4.4 bar (63.8psi), complete with Adaptor and gauge guard |

| MANHOLE |

500mm low profile, 8 point fixing. The manlid is completedwith TIR |

| AIR INLET ASSEMBLY |

DN 40 ball valve terminating with 1½” BSP connection and cap |

| TOP DISCHARGE PROVISION |

DN80 stainless steel 316 tank pad with not less than 94mm hole with blind flange. The assembly is fitted off centre on a low profile horizontal tank pad. Flange to be dual drilled: 6×M12 on 168.3PCD and 4×M16 on 160PCD |

| BOTTOM DISCHARGE |

FV: DN80 30° Univalve footvalve terminating with a 3″ BSP spigot with cap and chain. Perolo: DN80 30° TWINCO footvalve terminating with a 3″ BSP spigot with cap and chain. The bottom flange is a normal flange. |

| STEAM HEATING |

8 runs steam heating system. Longitudinal steam channels manufactured from Duplex stainless steel. Heating provided to BDC area. Actual heating area 4.57 m2, effective heating area 9.6m2. |

| PRESSURES |

4 bar working pressure |

| CONNECTIONS |

1″ BSP inlet, 1″ BSP outlet. Stainless steel dustcaps fitted. |

| INSULATION |

50mm Rockwool where possible. |

PETIKEMAS offers competitive rates for 20’ ISO TANK CONTAINER short-term or long-term rental.

Contact us for more information

PETIKEMAS offers competitive rates for 20’ ISO TANK CONTAINER short-term or long-term rental.

Contact us for more information